The maximum recommended number of interlayers sandwiched between two sheets of glass is four.

If a project requires a frosted look for design or privacy reasons, a translucent color can be created by adding one of the Vanceva white interlayers to the color mix. Please note that the introduction of a white in a position other than the middle of a symmetrical color (e.g., 0292 versus 1292) will change the reflected color from side to side.

Two of the 16 foundation colors—color 9 (Arctic Snow) and color A (Cool White)—are translucent white interlayers. Cool White is an 80% light-transmission product and Arctic Snow is a 65% light-transmission product. When these interlayers are used in the Vanceva system, they add translucency to the glazing system. These layers can be used in combination with the other 14 colors or can be laminated alone to produce a frosted glass appearance.

The use of more than one layer of colors 9 or A creates greater obscurity, making the panel more translucent and less transparent. For example, color AA9A consists of a four-layer system, three layers of which are product A (Cool White) and one layer of product 9 (Arctic Snow). When combined in the four layers as such (AA9A), the overall light transmission is 40%. These products can produce interlayers with light transmission that ranges from 80% (color A alone) to 29% (color 9999).

Our distinctive Polar White, a near-opaque white color option with a 7% light transmission feature, further expands the design possibilities. Polar White can contribute to privacy dividers or solid walls giving the opportunity to design with glass while maintaining the look of a solid wall.

Click here to design a two-sided color sample.

A given color is repeatable within Eastman specifications. For bigger projects, we recommend the use of interlayers produced in one production batch.

A Vanceva formulation code is an identification number for a particular color. One to four layers of interlayer are typically used for the construction of the laminated glass. Since the maximum number of interlayers is four, each color composite has been assigned a four-digit number. Click here to watch a demo.

Visit the Vanceva Color Families to get an overview of the range of colors. This is not an exhaustive rendering since the colors are depicted in clear glass only. The combinations are endless.

Please note that, for your final decision, you should always have a glass sample representative of the final color, desired glass thickness, coating, and other decorative attributes to be specified on your project. The color combinations displayed within the color selector tool provide a basic color impression but, due to monitor and printing technology, cannot correspond exactly to the final laminated glass. Click here to order a sample.

Please note we can only send you the samples with a maximum lead time of two weeks. SAMPLES CAN ONLY BE ORDERED VIA THE WEBSITE.

This center maintains a database that cross-references Vanceva colors to standard color pallet systems that can be used as a means of communicating color requirements in lieu of submitting samples.

Once a glass sample color is approved, the preparation of an insulated glass (IG) unit will require the assistance of a laminator and/or a window company. For a list of partner customers who can fabricate an IG unit mock-up, click here to go to our Glass Manufacturers Locator.

In case of asymmetric combinations (e.g., 4558), please inform your supplier which side needs to be on the outside. The perception of the color will be slightly different on each side.

No, Eastman does not advise the use of any interlayers, clear or colored, in combination with Vanceva interlayers unless they are an approved Saflex brand.

The Vanceva color system can produce a broad spectrum of colors that are unachievable using stock selections of glass. The system is based on 16 basic colors that can be combined in up to four colored layers to produce individual colored glass. Vanceva color interlayers can be combined to produce over 17,000 transparent, translucent, or opaque color options to help you create the perfect tone and intensity.

A Vanceva color interlayer formulation code is an identification number for a particular color. One to four sheets of interlayer are typically used for the construction of the laminated glass. Because the maximum number of interlayers is four, each color composite has been assigned a four-digit number. Click here to watch a demo.

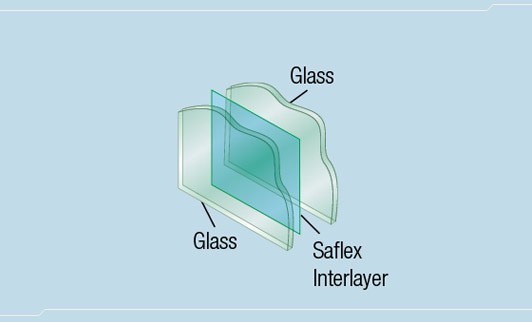

Laminated glass consists of a tough protective interlayer made of polyvinyl butyral (PVB) bonded together between two sheets of glass under heat and pressure. Once sealed together, the glass "sandwich" behaves as a single unit and looks like normal glass. Annealed, semi-toughened, strengthened, or tempered glass can be used to produce laminated glass.

Laminated glass provides durability, high-performance, and multifunctional benefits while preserving the aesthetic appearance of the glass. When impacted, laminated architectural glass will typically remain intact and may help prevent further damage caused by shattered glass.

Laminated glass can be used virtually anywhere standard glass is used with very few exceptions. Some of the most common applications are:

The Vanceva color system is a range of colored PVB (polyvinyl butyral) interlayers. The Vanceva color interlayer system can produce a broad spectrum of colors and atmospheres that are unachievable using stock selections of glass. With this system, interlayers can be combined to produce over 17,000 transparent, translucent, or opaque color options to help you create the perfect tone and intensity.

Laminated glazing is formed by permanently bonding these protective interlayers between two or more sheets of glass, creating a product that can meet or exceed some of the most stringent safety and security standards worldwide.

No, Eastman is a manufacturer of glazing interlayers; Saflex is a brand name for those interlayers.

Vanceva color interlayers have been successfully used in a huge variety of projects since being introduced in 1988. The product is also used in other applications, such as furniture, interior glass-wall systems, curtain walls, skylights, staircases, retail shelving, flooring, and more. Click here to visit our gallery.

Eastman manufactures laminated glazing interlayers and supplies these interlayers, branded as Saflex® polyvinyl butyral and Vanceva® color interlayer system, to our partner customers who laminate them within glass. These laminating companies have a sales staff who can advise you on your project. Eastman does not maintain its own showroom. Glass Manufacturer Locator

Eastman manufactures laminated glazing interlayers and supplies these interlayers, branded as Saflex® polyvinyl butyral and Vanceva® color interlayer system to our partner customers who laminate them within glass.

Please click here for a list of qualified fabricators who can provide price quotations for a specific project.

Among the factors that affect the price of laminated glass systems are the number of interlayer pieces within the glazing system and the type (thickness, strength, performance, etc.) of glass that will be used in the lamination.

Laminated glass made with Vanceva color interlayers can be purchased from selected glass manufacturers or laminators.

Click here for a listing of glass manufacturers.

The interlayers we manufacture are used by glass companies to fabricate laminated glass. These glass companies then sell the laminated glass to manufacturers of insulated glass windows and doors, furniture and interior glass-wall systems, curtain walls, and skylights so that they can fabricate the glass into the finished installed product.

If you are an individual/ private person, kindly note that we are not supplying glass. Please contact your nearest glazier.

Please visit our Vanceva Color Selector Tool to explore available colors. SAMPLES CAN ONLY BE ORDERED VIA THE WEBSITE.

If you know your four-digit Vanceva color combination reference, you can type this into the field "Enter a Vanceva Color Code” found in your shopping cart.

The samples are 10 x 10 cm glass laminates with 2.3-mm glass.

Custom sized samples can be produced by the laminated glazing manufacturer.

If you have any additional questions, please contact us.

1. Login to your account

2. Click on My orders

3. Search for your order

4. Click on the PDF document to download and/or print your invoice

Eastman advises the use of strengthened laminated glass to avoid thermal breakage. Thermal breakage may occur everywhere, from hot countries (e.g., Spain) to cold regions (e.g., Scandinavia).

Consequently, it is recommended to assess the risk of thermal breakage for EACH project where Vanceva will be used for exterior applications (facades, roofs, sunscreens, balconies, etc.). If the simulation shows that there is a risk, heat-strengthened or fully tempered glass should be used in place of annealed glass. Of course, for indoor applications (partition walls, balustrades, etc.) the risk of thermal breakage is slight, as there is usually no direct sun radiation on the laminated glass.

Eastman cannot and does not recommend specific sealants. Eastman has extensive experience with sealants using Saflex® PVB interlayers. The thoroughness of the application of sealants is just as important as the chemical interactions between the sealants and the PVB. The least reactive sealant poorly installed will perform worse than the most reactive sealant properly installed. Other effects, such as physical performance, weathering, paintability, and application ease, enter into the decision of which sealant to use. Often the framing will hide any cosmetic effects that may appear at the edge of the glass. To view documented results of compatibility testing of commonly used sealants and Saflex interlayer products click here. Most sealant suppliers will give information on which of their sealants is compatible with PVB interlayer.

Yes. Examples for exterior applications include: doors, windows, curtain walls, wall coverings, and overhead glazing.

Eastman recommends assessing the risk of thermal breakage for EACH project where laminated glazing featuring Vanceva colors will be used for exterior applications (facades, roofs, sunscreens, balconies, etc.). If the simulation shows that there is a risk, heat-strengthened or fully tempered glass should be used in place of annealed glass. This simulation should be carried out by your glass supplier. Click here to go to our Glass Manufacturer Locator.

Only a glass manufacturer can offer a warranty on the final glass construction.

Laminated safety glazing made with Vanceva color interlayers contains at least one PVB interlayer with a minimum thickness of 0.38 mm. They, therefore, can meet most impact safety glazing requirements when properly laminated. Some countries require a minimum of 0.76 mm to meet the human impact safety glazing requirements; this can be accomplished with two or more layers of Vanceva or one layer of Vanceva and a layer of clear PVB. Certain Vanceva colors are also produced in 0.76 mm thick to accommodate this requirement.

All architecturally targeted Vanceva interlayers will screen out 99% UV radiation up to 380 nm (including UV-A, B, and C).

Vanceva colorants are highly resilient and are designed to provide years of color durability. We have 20 years of experience in exposure through applications.

Extensive testing has been done on the hue stability of all Vanceva brand polyvinyl butyral colored interlayers. These products have been subjected to extensive natural and accelerated exposure testing. This testing concludes that there is no significantly adverse color shift (yellowing or otherwise) in these products when laminated and installed in accordance with Eastman’s generally recognized methods as outlined in the Saflex® Lamination Guide.

For optimal color durability, we recommend not exposing the following Vanceva products to direct sunlight: yellow layers Sahara Sun and Golden Light (colors 4 and 8) as well as Tangerine (color E). For direct exposure applications, we recommend embedding these layers by one or more layers of clear or other-colored PVB interlayer (e.g., 0343 or 0585).

The colors are layered between two sheets of glass. As the color is in the interlayer and protected by the two sheets of glass, cleaning and maintenance is easy and has no detrimental effect on the appearance. The edges of the laminated glass should always be kept dry. Any moisture or solvent that comes in contact with the laminate edge during cleaning should be immediately wiped dry and not allowed to sit and evaporate or absorb into the interlayer.

If you have a question on the color stability over time for a specific case, please contact us.

Yes, it is possible in simple curved glazing. Please contact the laminators who can provide price quotations for a specific project. Click here to go to our Glass Manufacturer Locator.

3.22 meters is the maximum width available for Vanceva color interlayers.

Testing conducted in both natural (Florida) and accelerated xenon weathering exposures have confirmed that—by all measurement systems—when properly laminated and installed, glass laminates produced with Vanceva design interlayer will provide acceptable quality when the edges of the laminate are exposed to normal weathering.

Visit http://www.vanceva.com for more information, to order product samples, to design your own color combination, and more.

You may enter as many projects as you like from multiple countries. The only stipulation is that the project cannot have been submitted previously to an Eastman competition.

No.

The Vanceva World of Color Awards was born to honor architects and interior designers whose use of laminated colored glass, made with Vanceva interlayers, was deemed the best among entrants with special consideration for the following criteria:

1. Creative use of laminated color glass

2. Relation to new and developing applications of laminated glass

3. Overall aesthetics of project

4. Degree of attention paid to laminated glass benefits

Architects, interior designers, glass laminators and fabricators, and Eastman employees and associates are eligible to enter projects into the competition. The contest is open to individuals and companies from around the world that have used Vanceva interlayers for laminated glass in their project designs. Projects submitted from previous Eastman competitions are not eligible for consideration.

Vanceva color interlayers for laminated glass are used around the world by leading glass manufacturers.